Lean Manufacturing & Quality Training

For over 30 years, plastics manufacturers have trusted Routsis to help streamline production and improve part quality. Today, our online training courses are used by thousands of individuals in manufacturing facilities and educational institutions around the world.

The 5S System

Implementing Lean Manufacturing principles has never been easier: Our online 5S training programs will help your facility reduce clutter and waste — and ultimately increase efficiency and productivity.

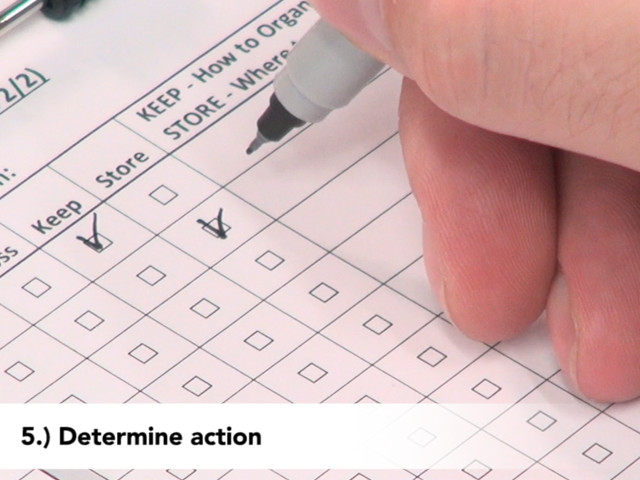

Each course in this 5-part series focuses on a particular step of the 5S System: Sorting, Straightening, Sweeping, Standardizing, and Sustaining. These courses are built on Routsis Training’s exclusive SkillSet™ training model, which combines online videos with hands-on worksheets. This innovative approach allows companies to perform the same type of classroom learning found in popular seminars in the comfort of their own production environment.

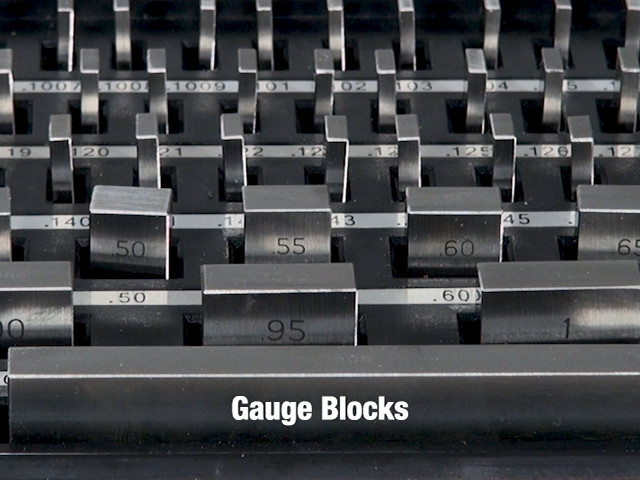

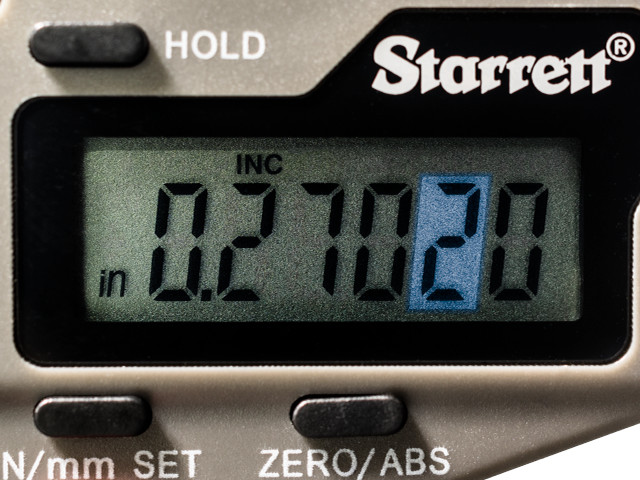

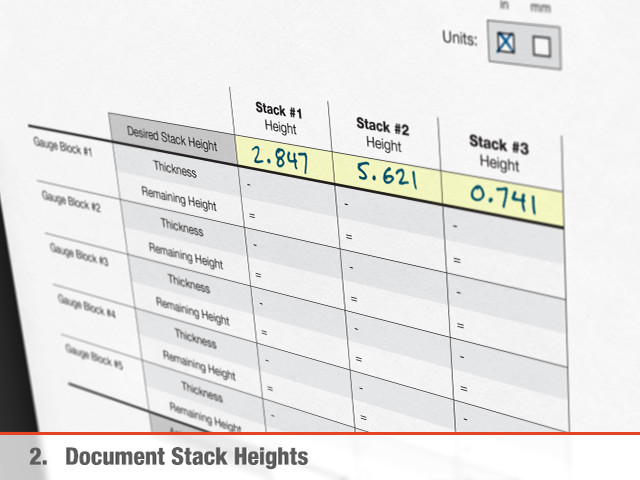

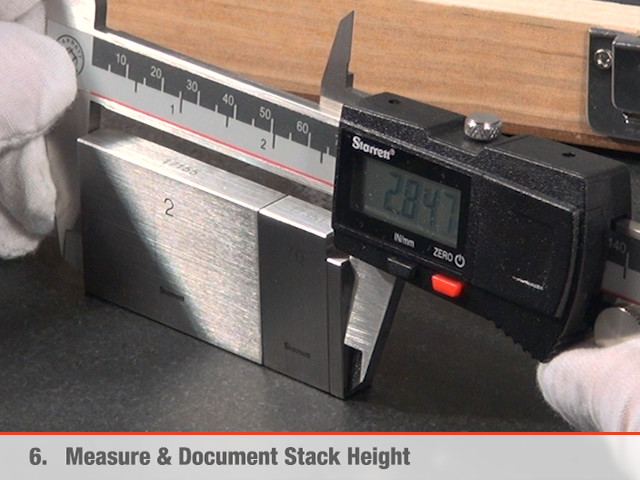

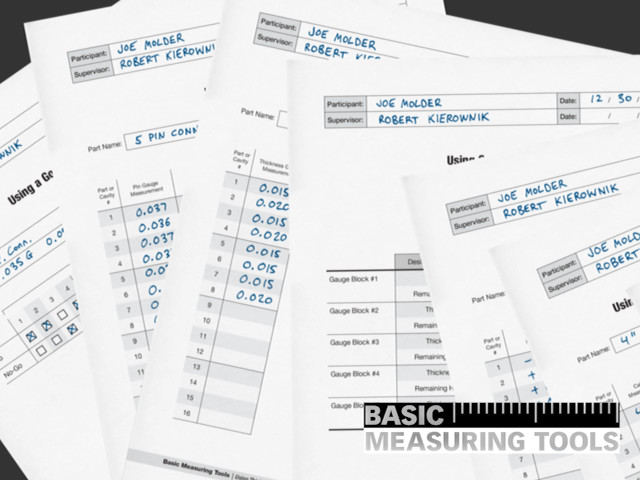

Basic Measuring Tools

This comprehensive training program consists of 21 SkillSet™ training labs. The courses cover pin gauges, linear indicators, slide calipers, micrometers and other tools regularly used by quality assurance and quality control personnel.

Each of the twenty-six video/worksheet combinations focuses on a particular measuring tool. The steps outlined in each course ensure the tool is being used properly — and providing reliable measurements.

Users learn best-practices for handling and storing measuring equipment — and how to stabilize tools and part features for improved accuracy. Procedures for verifying the accuracy of each tool — often referred to as “field-checking” — are also covered.

Math Skills for Ensuring Quality

In a modern manufacturing environment, it’s critical for personnel to have a working knowledge of mathematics. We’ve created courses that specifically cover math concepts and calculations commonly used by production and quality personnel. Participants begin with a review basic of arithmetic and learn how to correctly use a calculator. Next, important concepts such as calculating averages, percentages, rounding numbers, converting between metric and imperial units, and order of operations are discussed. Users will also learn to calculate area, volume, flow, weight, mass, and force.

We offer 3 different versions of this training program; each focusing on a particular plastics manufacturing process.